A meaningful trophy

The trophy for the 2024 KITE Award was designed and realised by apprentices from the physics department. This project came from the winners of the last KITE Award.

A team from the physics department's Physics Lab consisting of Andreas Eggenberger, Martin Kroner, Max Doebeli, Marius Simon, Adrian Biland and Alexander Eichler has donated this year's trophy for the winners of the KITE Award. This continues a tradition according to which the KITE Award trophy is chosen by the most recent winners of this award.

As the trophy had to be playfully physics-related, explains Alexander Eichler, the team chose a so-called eddy current brake: a magnetic ball falls through a non-magnetic cylinder made of aluminium, which is a good electrical conductor. Inside the cylinder, the magnetic field changes as a function of time and induces an electric current that generates a secondary magnetic field. As the two magnetic fields point in opposite directions, the falling ball slows down drastically, so much so that it appears to float inside the cylinder and only accelerates again upon exiting it.

The project team found a satisfying association between the physical effect and the dynamics of learning processes, where some initial resistance may need to be overcome and learning success may arrive with a delay. In this sense, the trophy embodies playful and fascinating aspects of physical phenomena while encouraging reflection on learning dynamics.

The project team awarded the contract for building the trophy to the Engineering Office of the physics department, with the additional request that the aluminium cylinder be part of a larger construction designed to hold the falling ball. Laurin Nägeli, second-year apprentice designer, saw the project team's sparse specifications as a creative challenge and identified a special design for the trophy: the cylinder rests loosely on an inclined perspex bridge, the extension of which holds the ball once it leaves the cylinder. Using perspex makes the cylinder look like it floats; the project team was impressed by Laurin's innovative design.

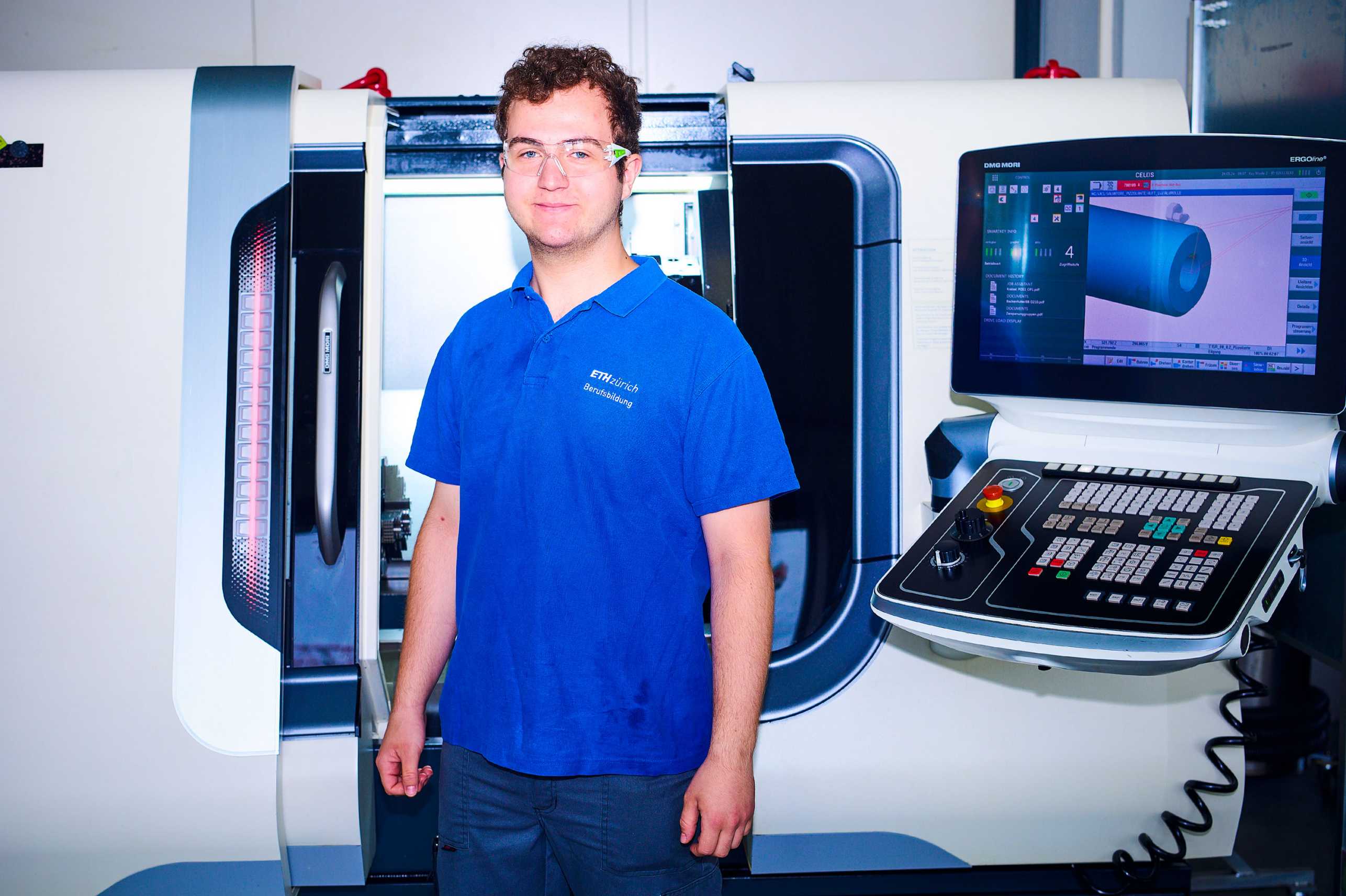

Apprentice polymechanics Tim Hausmann, Salvatore Pizzolante and Jeremy Klein produced the individual parts of the trophy according to Laurin's plans in the physics department's workshop. Tim was responsible for the base plate and Salvatore for the aluminium cylinder. Jeremy realised the perspex parts, which proved complex to produce due to their chamfered edges. All finished parts were given to Laurin, who took care of the final assembly of the trophy. The apprentices completed all parts on time.

Laurin and his coworkers are proud of the outcome of their work, which saw them realise a unique trophy where creative solutions and technical skills were successfully combined. The apprentices' work also impressed the award's organising committee as well as Rector Günther Dissertori. The KITE Award finalists can now enjoy the trophy and get inspired about what message they would like to pass on to the next finalists, who will be announced in 2026.

This project could be realised by apprentices as part of their regular assignments thanks to the Engineering Office, the Mechanical Training Workshop and the Mechanical Workshop of the Department of Physics.

Walter Bachmann, Head of the Engineering Office, gave Laurin input on the design and construction aspects. Head of the Mechanical Workshop Andreas Stuker and his deputy Bernhard Morath supported the apprentices as they planned their work, kept to the timetable and realised the trophy. The team from the department's Mechanical Training Workshop and Marcel Wachter, part-time vocational trainer, supported the apprentices during the production phase.

Translated from German by Gaia Donati